Siemens Simcenter: Advanced Simulation and Testing Solutions for Product Development

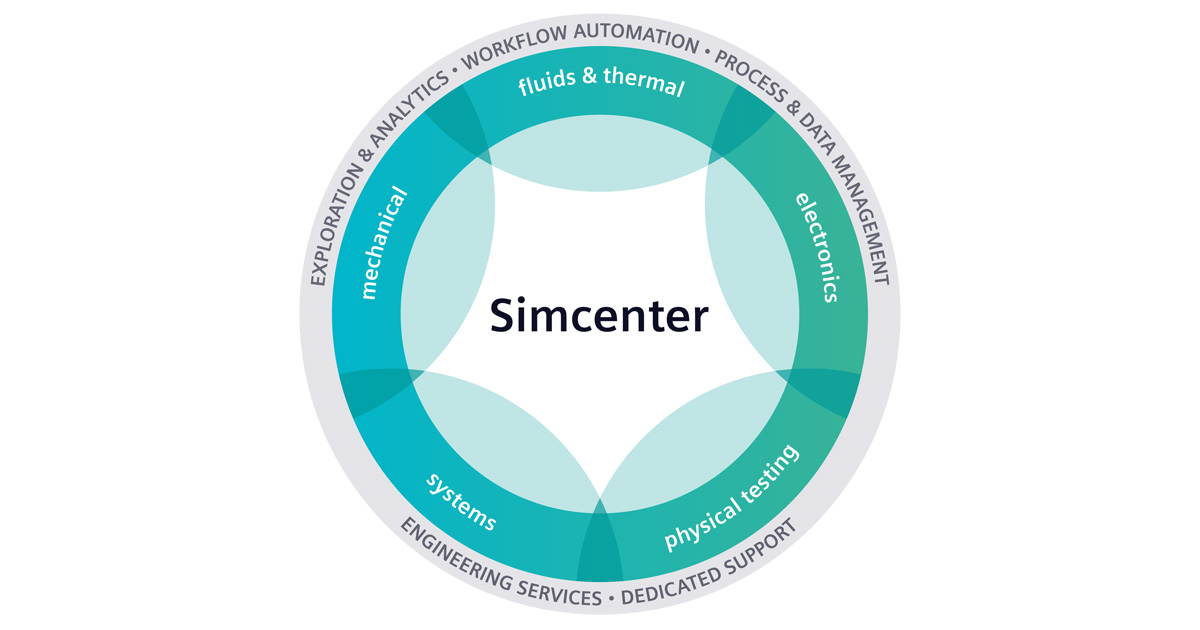

Siemens Simcenter is an integrated suite of simulation and testing solutions designed to accelerate product development by optimizing the design and performance of complex systems across multiple industries, including automotive, aerospace, energy, and manufacturing. Simcenter enables engineers to predict real-world performance using advanced multiphysics simulation, computational fluid dynamics (CFD), finite element analysis (FEA), and thermal analysis tools, combined with real-time testing capabilities.

With Siemens Simcenter, organizations can simulate and validate mechanical, electrical, thermal, and fluid interactions in their designs, allowing them to develop high-performing, efficient, and sustainable products. Simcenter’s model-based systems engineering (MBSE) approach allows for a comprehensive view of product development, ensuring that components and systems work together seamlessly.

Simcenter also integrates with Siemens' broader PLM (Product Lifecycle Management) tools, creating a unified platform that connects product design, development, testing, and deployment. By utilizing digital twins, Simcenter helps companies improve product quality, reduce development costs, and shorten time-to-market, all while ensuring compliance with industry standards and regulatory requirements.

-

Key Benefits:

-

Comprehensive simulation and testing tools for predicting real-world product performance.

-

Supports multiphysics simulations, including CFD, FEA, and thermal analysis.

-

Accelerates product development by integrating simulation with real-time testing.

-

Model-based systems engineering (MBSE) for optimizing complex systems and components.

-

Helps reduce time-to-market, improve product quality, and ensure regulatory compliance.

-

For more information, visit the official product page: Siemens Simcenter

Similar Products

Nuvation Energy BMS

Nuvation Energy BMS: Advanced Battery Management System for Efficient Energy Storage Nuvation Energ…

Lithium Balance BMS

Lithium Balance BMS: Intelligent Battery Management for Advanced Energy Storage Solutions Lithium B…

Elithion Lithiumate Pro

Elithion Lithiumate Pro: Advanced Battery Management System for High-Performance Lithium-Ion Applic…

AVL eSuite

AVL eSuite: Comprehensive Software Solution for Vehicle Electrification and Powertrain Development …

MathWorks MATLAB

MathWorks MATLAB/Simulink: Advanced Modeling and Simulation Platform for Engineering and Research M…