How AI Can Optimize Production Lines in Small Manufacturing Businesses

Today, in this fast-changing era of bunches and bindles of technologies, Artificial intelligence (AI) has taken up the revolutionary role among all sectors where manufacturing is one such sector that falls under AI’s brighter side. The deployment of AI into the manufacturing process represents a qualitative leap towards optimizing ever more efficient, accurate and value-driven production. A technological development that is no longer the exclusive domain of massive factories, but one that’s available to smaller businesses as well, shortening and levelling the playing field with in turn giving small-batches manufacturers new opportunities for growth and innovation too.

In this article, we would dive into how small businesses within the manufacturing industry could leverage AI to streamline their production lines. Leveraging AI technology, these business can increase their efficiency to build greater benefits throughout the economy that translate to lower production costs and high-quality products and services, gaining a competitive advantage. I hope this discussion offers you some takeaways while giving a better idea of how AI is transforming small scale manufacturing. To know about more opportunities and possibilities be sure to leave your questions in the comment section below!

Artificial intelligence, or AI, is the power of a machine to imitate intelligent human behavior. In simple words, AI makes it possible for machines to learn from experience, adjust to new inputs as well as perform human-like tasks. What is a human-like task? When I say Humans like tasks: Understanding Spoken language; Interpreting meaning out of sentences heard — Analyzing and making decisions etc. AI in a manufacturing context can also include machine learning (ML), an application of AI that provides systems the ability to automatically learn and improve from experience without being explicitly programmed, robotics — robots are basically machines— or even just computer vision.

Key terminologies in AI relevant to manufacturing include:

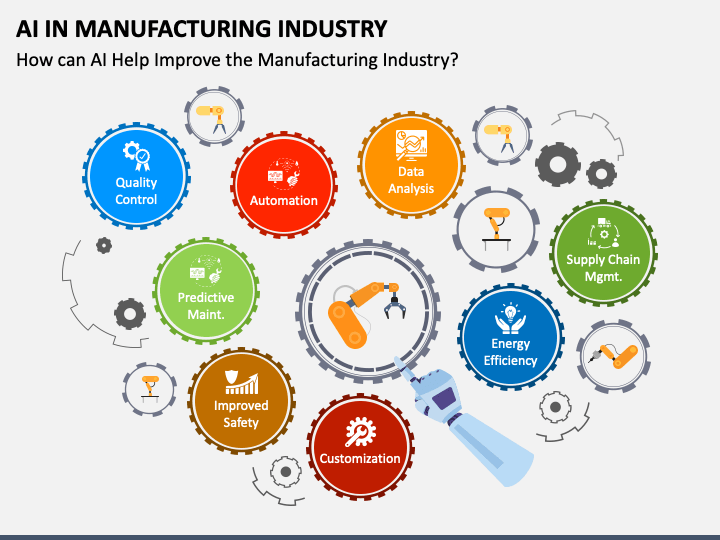

Over the last decades, it is fair to say that the adoption of AI in manufacturing has grown at an unprecedented pace. At first, AI was mostly about a type of automation—replacing the boring tasks that humans did with robot ones. However, nowadays more advanced applications characterized with predictive maintenance, quality forecasting and supply chain optimization have become leading directions.

AI capabilities in the manufacturing sector have matured to provide more than just enhanced production efficiency. A multitude of areas, from safety to product development and customization are essentially revolutionizing processes. the evolution of Industry 4.0, which refers to the fourth industrial revolution involving a more dynamic integration and process that involves cutting edge technology and is blurring the boundaries between physical, digital, and biological domains. With real-time data analysis, among other possibilities, you can measure the results and adjust operations at a moment’s notice to minimize waste and optimize production.

The greatest advantage that comes from introducing AI, however, is the notable improvement in overall operational efficiency for small manufacturing businesses. Artificial Intelligence tools especially in forecasting and predictive analytics can help you streamline operations by accurately predicting accurate production schedules, minimizing equipment downtime using trend-based predictive maintenance as well as reducing human errors. Take an AI system analyzing huge volumes of operational data to forecast when a machine is at high risk of failure or will need maintenance, so the organization can prevent unexpected downtime and costly interruptions.

A small automotive parts manufacturer that has rolled out AI-enabled predictive maintenance on its machinery. This reduced downtime by nearly 20% and increased production throughput by 15%.

AI helped a boutique electronics firm to streamline their supply chain and inventory management, lowering surplus stock levels by 30% while also guaranteeing that they never ever lack vital substances.

These are examples to show how even a modest implementation of AI can drive enormous efficiency gains and thus transform the bottom line for small businesses

AI is critical for improving quality control practices in manufacturing as well. From advanced imaging to AI-driven data analysis, tiny defects that would have come unnoticed by humans are eventually detected. A computer vision system can check hundreds of items per minute with near-unerring consistency and accuracy, far more than any puny human could ever hope to achieve. These systems learn, in real-time from every inspection, enhancing their ability to identify even the smallest of anomalies.

As a result, implementing AI-driven quality control systems permits small manufacturing businesses to attain higher standards of product quality, which is critical for the sustenance of customer satisfaction and competitive advantage. Take a small textile manufacturer that uses an AI-powered, visual inspection system to scan fabrics and check for defects while travelling at rapid speeds, ensuring only top-tier supplies enter the market.

Machine learning (ML) is transforming the way small manufacturing companies handle and protect their machines Using ML models, such businesses can predict failures before they happen. However, that predictive ability is not just in identifying when a machine is likely to fail; but it’s also understanding their usage trend of wearing out and replacing the component and at what times we will carry maintenance without derailing our production cycles.

How it works: The ML algorithms assess historical data obtained from sensors on machinery and detect patterns or anomalies that occurred before breakdowns. Then the system can actually send alerts for preventative maintenance, saving on maintenance costs and preventing unplanned downtime that can be devastating to smaller businesses working with smaller margins.

That means, for instance, a boutique manufacturer of high-tolerance tools might use ML to track how well its drills are running. It could even predict bearing failures from the vibration data, enabling maintenance to be planned and conducted during scheduled downtimes so that there is little or no disruption in production due to unexpected breakdowns.

Smart robotics commonly known as robotics integrated with AI can help manage repetitive and physically challenging tasks. This synthesis could mean substantial productivity improvements, greater product quality uniformity and improved worker’s conditions for small businesses.

These smart robots can learn and adjust to new tasks easily, meaning they perfectly suit small manufacturing environments which are need regularly switching between products on their production lines. This switch-over time is significantly reduced compared to traditional robotics, where reprogramming the robot for each new task would be a long-winded and painstaking process.

For example, a small firm that makes high-end, custom furniture might use AI-powered robotic arms to perform the extremely precise cutting and assembly of different pieces of wood. In the future, robots of this nature will be able to conform automatically to varying design specifications without the extended stoppages required for manual retooling.

Scalablity is yet another benefit of this robots and automation integrtaed with AI, which in turn can be a boon for small scale enterprises. Initially, they may install one robotic unit to take care of one production process. As the business advances and as costs for technology continue to lower over time, they can increase their use into more processes while keeping an eye on increasing their efficiency and productivity.

Small manufacturing businesses should consider how ready they are to take on these new technologies before diving in. Here’s a checklist to arrive at whether or not a small manufacturing business is ready yet, for the AI plunge:

If you are looking to make things happen with AI in a small manufacturing operation. Click through to read the following step by step guide if you run a small business and are keen to embark on that transformation:

The cost of implementing AI into production line can be quite the monetary investment, especially for small companies. Such upfront costs can extend to new hardware and software investments, as well as infrastructure changes in some cases to equip organizations with the resources needed for AI implementations. Another cost is training staff to use and care for these new systems.

Nevertheless, although these upfront costs may be high, the return on investment (ROI) can well outweigh them for many projects involving AI. AI can drive significant cost savings in the long run by reducing inefficiency, downtime and human errors. Predictive maintenance, for example, can reduce repairs and contribute to longer life of machines in a big way. What’s more, the accuracy and speed of AI-powered manufacturing can increase production volume and enhance the goods themselves — creating new market segments while enhancing customer experiences.

Before investing in AI implementation, businesses weighing the benefits of integrating artificial intelligence should carry out a total cost-benefit analysis to measure the ROI. This projection includes comparing gains from increased production efficiency and new market creation against initial outlay as well as ongoing expense.

While AI systems within the manufacturing environment are data-driven, there are security and privacy implications around that data. - This involves securing your proprietary information and protecting sensitive business data against cyber threats or unauthorized access.

When using AI systems, some key considerations need to be addressed around data security and privacy. Those are:

Strong security and staying on top of the latest threats is crucial to protect a business’s IP and sensitive data – which are often synonymous with competitive differentiation.

Given that AI technology only continues to evolve, the future of its uses in smaller manufacturing settings are looking brighter and better. • Greater possibilities: We can also look porward to other further advancements that would greatly improve the manufacturing process.

Taking that into consideration, small businesses can take advantage of these future developments with ease by being informed and flexible as they become a mainstream reality. To stay competitive, implement these smart strategies:

The addition of Artificial Intelligence AI in small manufacturing businesses brings with it a life-altering potential that could redesign your production processes, improve workability efficiency and increase product quality. Machine learning, robotics and predictive maintenance are tools in the arsenal of AI technologies that help small businesses automate processes, minimize downtime opportunity and predict repair or replacement required saving costs as well as increasing overall productivity.

In addition, if AI-powered quality control can already greatly enhance the overall product standard by detecting defects that may have otherwise been overlooked by human error this is enough to secure customer preference. As we move forward, AI’s advancing capabilities indicate further breakthroughs will be achieved in the future, meaning it is crucial small businesses integrate and incorporate these technologies to remain relevant in an ever-evolving market.

1. What is AI in the context of manufacturing?

Artificial Intelligence (AI) in manufacturing involves using advanced algorithms and technologies to enhance various production processes. This includes machine learning, predictive analytics, robotics, and computer vision, all aimed at improving efficiency, reducing costs, and enhancing product quality.

2. How does AI improve efficiency in manufacturing?

AI improves efficiency by optimizing production schedules, reducing machine downtime through predictive maintenance, and streamlining supply chain management. It enables real-time decision-making and adjustments that can lead to more effective use of resources.

3. Can AI in manufacturing reduce operational costs?

Yes, AI can significantly reduce operational costs by minimizing waste, improving energy efficiency, and reducing the frequency and severity of machine failures through predictive maintenance. It also reduces labor costs by automating repetitive and physically demanding tasks.

4. Is AI integration suitable for all types of small manufacturing businesses?

While AI offers extensive benefits, its suitability can vary based on specific industry needs, the complexity of the production processes, and the scale of operations. Businesses should conduct a thorough feasibility study to determine if AI integration will meet their specific objectives.

5. What are the initial steps a small manufacturing business should take to integrate AI?

Start by assessing AI readiness through audits of current systems and processes, identifying areas that could benefit from AI, and defining clear business objectives. Then, consider partnering with AI technology providers who can offer tailored solutions and support pilot projects to gauge effectiveness before full-scale implementation.

6. What challenges might a small business face when implementing AI in production lines?

Challenges include the high initial cost of technology, the need for skilled personnel to manage AI systems, potential resistance to change from employees, and ensuring data security and privacy. Overcoming these challenges requires strategic planning, training, and possibly phased integration of AI technologies.

By adopting tools like AI, predictive analytics, and cloud-based command systems—and by integrating them through Virtual Delivery Centers—COOs can convert uncertainty into action and fragility into resilience.