Technical Textiles: From Construction to Healthcare, How AiDOOS Supports Growth in a Specialized Industry

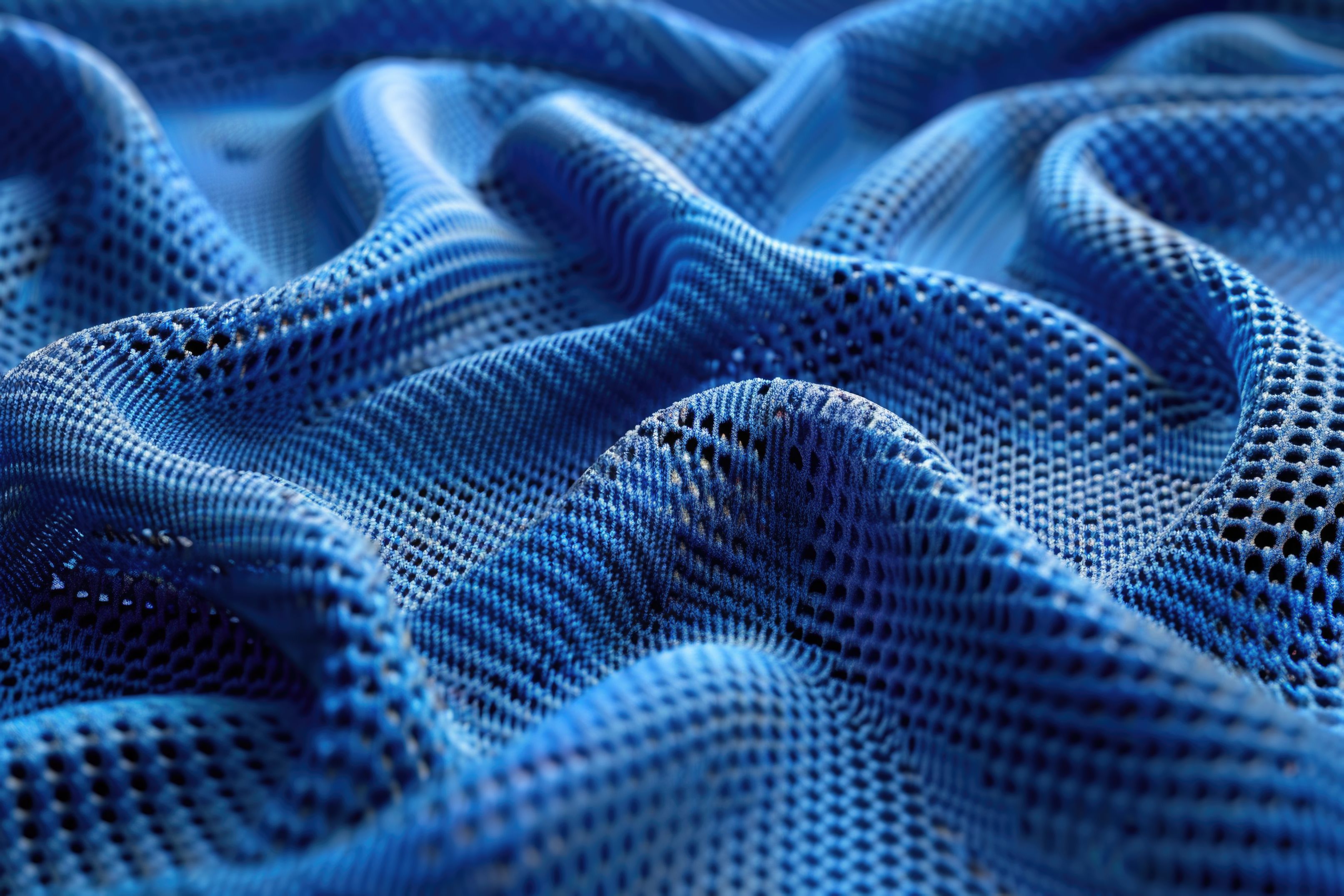

Not all fabrics are created equal. Some are designed to keep us comfortable, while others must withstand extreme conditions, save lives, or drive industrial innovation. Welcome to the world of technical textiles, a highly specialized segment of the textile industry that serves diverse applications, from construction and automotive to healthcare and aerospace.

Technical textiles are engineered for performance. These high-performance fabrics offer properties such as flame resistance, waterproofing, durability, elasticity, and more, making them indispensable in industries where safety, functionality, and reliability are critical. Whether it’s the airbag in your car, the geotextile stabilizing the foundation of a highway, or the wound care dressing in a hospital, technical textiles are at work all around us.

However, manufacturing technical textiles is no simple task. It involves advanced research, rigorous testing, and strict adherence to industry-specific standards. The demand for innovation in technical textiles continues to grow, driven by the need for sustainable solutions, improved performance, and new applications in fields like healthcare and construction.

In this blog, we’ll explore the key challenges and opportunities in technical textile manufacturing and how AiDOOS is empowering manufacturers to innovate, optimize, and scale their production processes to meet the increasing demand for these specialized fabrics.

Technical textiles differ from conventional textiles in that they are designed primarily for their functional properties rather than aesthetic appeal. These fabrics are used in industries where strength, durability, and performance are critical, and they are engineered to meet the specific needs of each application.

Some common categories of technical textiles include:

Construction Textiles (Geotextiles): Used in civil engineering projects to reinforce soil, prevent erosion, and stabilize roads and foundations.

Medical Textiles: Used in wound care, surgical garments, and implants, providing essential functions such as moisture control, sterility, and biocompatibility.

Automotive Textiles: Found in seatbelts, airbags, interior components, and insulation, offering safety, comfort, and durability.

Protective Textiles: Flame-resistant, water-repellent, and chemical-resistant fabrics used in protective clothing for firefighters, military personnel, and industrial workers.

Technical textiles must not only perform under extreme conditions but also meet stringent industry standards and regulations. Manufacturers must constantly innovate to develop new materials with enhanced properties, improve production efficiency, and ensure that their products are sustainable and environmentally friendly.

Manufacturing technical textiles is a highly complex process that involves overcoming several key challenges:

Performance Requirements: Technical textiles must meet specific performance standards, depending on the industry they serve. For example, automotive textiles must be fire-resistant and durable, while medical textiles must be sterile and biocompatible. Meeting these requirements involves extensive research, testing, and quality control.

Compliance with Industry Regulations: Each industry that uses technical textiles has its own set of standards and regulations. For example, geotextiles used in construction must comply with environmental regulations, while medical textiles must meet healthcare safety standards. Ensuring compliance across different markets requires manufacturers to maintain rigorous quality assurance processes.

Sustainability: The demand for sustainable technical textiles is growing as industries seek to reduce their environmental impact. This requires manufacturers to develop eco-friendly materials and adopt sustainable production practices while still meeting the high-performance requirements of technical textiles.

Continuous Innovation: To stay competitive, manufacturers must constantly innovate, developing new technical textiles with improved properties, such as higher tensile strength, better thermal insulation, or enhanced moisture-wicking capabilities.

As manufacturers navigate the challenges of producing technical textiles, AiDOOS is providing them with access to the talent, technology, and solutions they need to innovate, optimize, and scale their production processes. Here’s how AiDOOS is transforming technical textile manufacturing:

Supporting Research and Development:

Innovation in technical textiles begins with research and development (R&D). AiDOOS provides manufacturers with access to top-tier experts in material science, engineering, and textile technology. These experts work alongside manufacturers to develop new fabrics with enhanced properties, from flame resistance to moisture control.

Tools like TexGen and ANSYS Fluent allow manufacturers to model the internal structure of textiles and simulate their performance under different conditions. This enables companies to experiment with new materials, optimize their designs, and ensure that their technical textiles meet the required specifications before moving to full-scale production.

Ensuring Compliance with Industry Standards:

Compliance is critical in technical textile manufacturing, where products are often subject to stringent safety and performance regulations. AiDOOS helps manufacturers streamline their compliance processes with platforms like Sparta Systems TrackWise and Veeva Systems Quality Management.

These platforms provide real-time quality control and documentation tools that ensure technical textiles meet the necessary regulatory standards across industries. By automating compliance documentation and generating audit trails, AiDOOS helps manufacturers avoid costly delays or recalls due to non-compliance.

Driving Sustainability in Technical Textile Production:

As sustainability becomes a top priority for industries such as construction, healthcare, and automotive, manufacturers must find ways to produce technical textiles that are both high-performing and environmentally friendly. AiDOOS provides access to sustainability management tools like Bluesign Technologies and Sustainability Accelerator, which help manufacturers measure and minimize their environmental impact.

These platforms allow manufacturers to track their resource usage - such as energy, water, and raw materials—throughout the production process and optimize it for sustainability. By integrating eco-friendly materials and processes, manufacturers can meet industry demands for greener solutions without compromising on performance.

Optimizing Production Efficiency:

Technical textiles often require complex manufacturing processes, involving weaving, coating, laminating, and finishing. AiDOOS provides manufacturers with automation tools like Texprocess and Siemens Opcenter, which streamline production and improve efficiency.

These tools enable manufacturers to monitor production in real time, identify inefficiencies, and automate key aspects of the manufacturing process, such as cutting and stitching. By optimizing production workflows, AiDOOS helps manufacturers increase output while maintaining the high quality required for technical textiles.

Case Study: Developing High-Performance Automotive Textiles

A technical textile manufacturer was tasked with developing a new line of automotive textiles that would meet strict safety standards while offering enhanced durability and comfort for vehicle interiors. The company needed to optimize its production processes to meet tight deadlines while ensuring compliance with automotive safety regulations.

By partnering with AiDOOS, the manufacturer gained access to experts in textile engineering and materials science. Using TexGen, the team was able to model and simulate the performance of various textile structures, testing for tensile strength, flame resistance, and comfort.

AiDOOS also provided the company with access to automation tools like Texprocess, enabling them to streamline production and increase efficiency. With real-time quality monitoring and compliance management, the company was able to meet the stringent safety standards required by the automotive industry.

The result was a successful launch of high-performance automotive textiles that exceeded industry expectations, positioning the company as a leader in innovative textile solutions for the automotive market.

As industries like construction, healthcare, and automotive continue to evolve, the demand for high-performance technical textiles will only grow. Manufacturers must stay ahead of the curve by developing new fabrics that meet the specific needs of these industries while ensuring sustainability, quality, and compliance.

AiDOOS is helping manufacturers achieve this by providing access to the talent, technology, and solutions needed to innovate and optimize their production processes. From supporting R&D to ensuring compliance and driving sustainability, AiDOOS is empowering technical textile manufacturers to create the next generation of high-performance fabrics.

Technical textiles are shaping the future of industries that rely on high-performance materials, from healthcare and automotive to construction and aerospace. As manufacturers face increasing demand for innovation and sustainability, they need the right tools and expertise to stay competitive.

AiDOOS is driving the future of technical textiles by providing manufacturers with access to cutting-edge technology, expert talent, and process optimization tools. Whether it’s developing new materials, ensuring regulatory compliance, or improving production efficiency, AiDOOS is empowering manufacturers to meet the challenges of today and the opportunities of tomorrow.

For modern telecom enterprises, delivering exceptional QoS is no longer optional—it’s a brand differentiator and a strategic lever for growth. Static provisioning models won’t cut it in a world of hyper-dynamic data usage.