Industrial Machinery: How Manufacturers Innovate in a High-Demand Industry

From powering factories to enabling energy systems, industrial machinery is the backbone of global manufacturing and production. These machines, designed for heavy-duty operations and large-scale manufacturing processes, drive productivity in sectors ranging from automotive and aerospace to energy and consumer goods. Industrial machinery encompasses everything from automated manufacturing equipment and robotics to turbines, pumps, and heavy-duty engines.

In today’s fast-paced and competitive market, manufacturers of industrial machinery face immense pressure to innovate, streamline operations, and integrate emerging technologies like automation, AI, and predictive maintenance. These challenges are compounded by the need for sustainability, efficiency, and regulatory compliance.

AiDOOS is helping industrial machinery manufacturers meet these demands head-on by providing access to technology talent, advanced R&D tools, and the right expertise to optimize production processes. In this blog, we’ll explore the key challenges faced by the industrial machinery industry and how AiDOOS is enabling manufacturers to drive innovation and efficiency.

Industrial machinery is fundamental to nearly every major manufacturing process across the globe. Whether it’s the assembly lines that produce vehicles, the turbines that generate power, or the pumps that keep water flowing, industrial machines are at the heart of modern industry. They’re designed to handle heavy loads, operate in extreme conditions, and work continuously to meet the high demands of production.

Some of the most common applications of industrial machinery include:

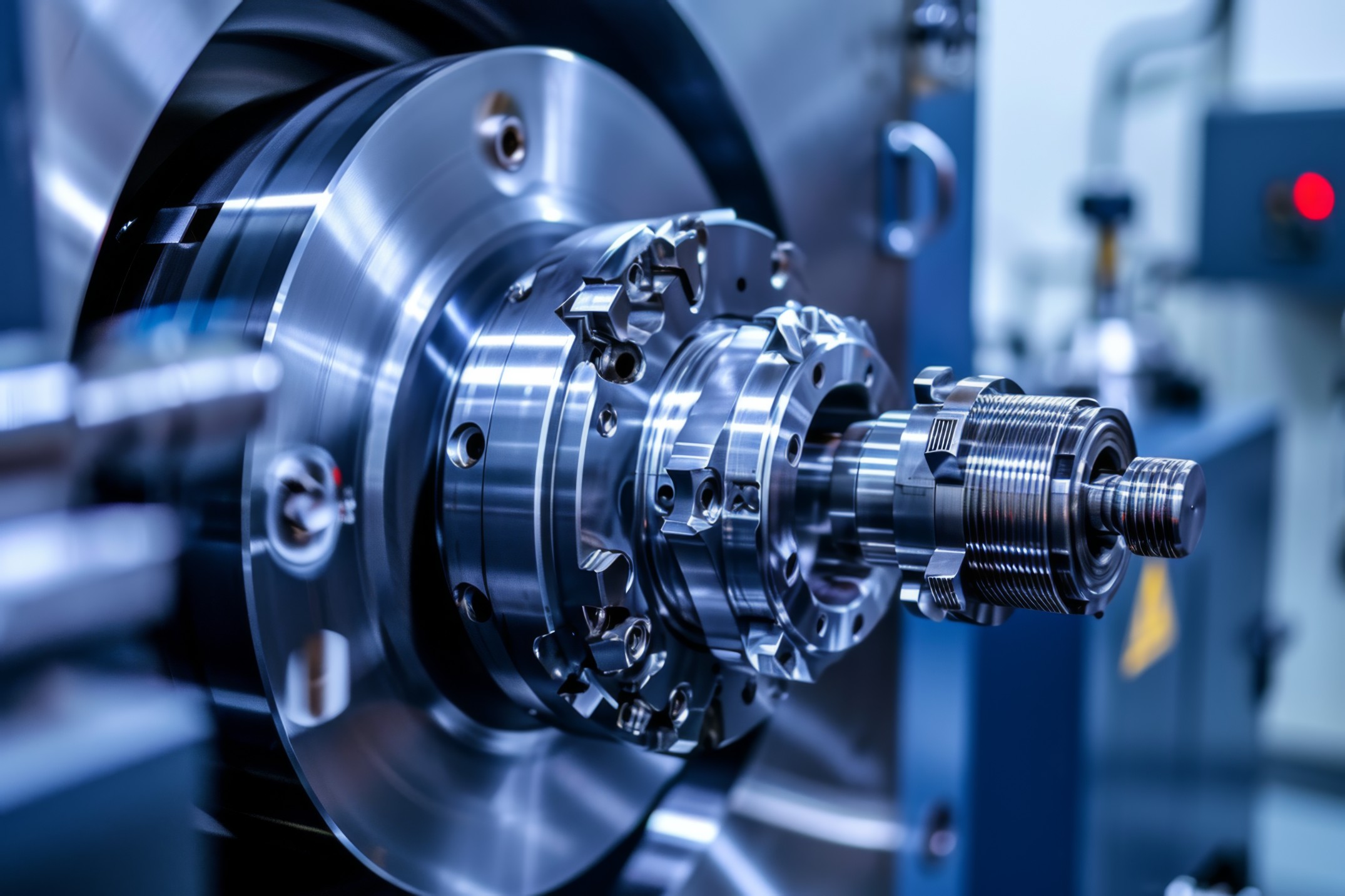

Manufacturing Systems: Automated assembly lines, CNC machines, and industrial robots used to manufacture cars, electronics, and household goods.

Power Generation: Turbines and generators used to produce electricity for industrial facilities, cities, and businesses.

Pumps and Compressors: Essential for industries such as oil and gas, water management, and chemical processing.

Heavy-Duty Engines: Found in everything from construction vehicles to ships, powering industries that depend on mobility and transport.

However, as industries become more automated and data-driven, industrial machinery manufacturers are faced with new challenges that require innovative solutions and cutting-edge technology.

Industrial machinery manufacturers must address a wide range of challenges to stay competitive, meet demand, and remain compliant with industry regulations:

Increased Demand for Automation: The rise of Industry 4.0 and smart manufacturing has led to an increased demand for automation in industrial machinery. Manufacturers must integrate robotics, AI, and automation solutions to enhance productivity and reduce human error in industrial processes.

Operational Efficiency: Machinery manufacturers must optimize every step of the production process, from design and testing to assembly and delivery. In a market where even small inefficiencies can lead to significant delays and costs, streamlining operations is key to staying competitive.

Sustainability and Energy Efficiency: As governments and industries push for greener, more sustainable operations, industrial machinery manufacturers must develop energy-efficient machines and systems that reduce carbon emissions and optimize resource usage.

Regulatory Compliance: In industries like oil and gas, power generation, and construction, industrial machinery must comply with stringent safety, environmental, and performance regulations. Ensuring compliance across different regions and markets adds another layer of complexity to the manufacturing process.

AiDOOS helps industrial machinery manufacturers overcome these challenges by providing access to the talent, technology, and tools needed to innovate and optimize their production processes. Here’s how AiDOOS is transforming industrial machinery manufacturing:

Streamlining R&D and Design Innovation:

Innovation in industrial machinery often starts in the research and development phase. AiDOOS provides manufacturers with access to top-tier engineers, designers, and R&D experts who specialize in industrial systems.

Platforms like PTC Creo and ANSYS allow manufacturers to design, simulate, and test machinery before it goes into production. Using these tools, manufacturers can optimize machine designs for efficiency, durability, and safety, ensuring that their products meet industry standards and performance requirements.

With the right talent and technology at their disposal, manufacturers can accelerate their R&D processes, bringing innovative machinery to market faster.

Integrating Automation and Predictive Maintenance:

As industries embrace automation, the demand for smart, automated machinery is growing. AiDOOS provides access to advanced technologies that enable manufacturers to integrate automation into their machines, including AI, robotics, and IoT (Internet of Things) solutions.

Tools like Siemens Digital Industries Software and Honeywell Forge allow manufacturers to develop machines with predictive maintenance capabilities, which can monitor performance in real-time and anticipate when maintenance or repairs are needed. This reduces downtime, prevents costly repairs, and extends the lifespan of industrial machines.

By leveraging these technologies, manufacturers can develop machines that enhance operational efficiency while reducing human intervention and error.

Optimizing Production Processes for Efficiency:

In a competitive market, optimizing production processes is essential for industrial machinery manufacturers. AiDOOS connects manufacturers with process optimization experts who specialize in streamlining manufacturing operations.

With platforms like Siemens Opcenter, manufacturers can digitize their production processes, automating tasks like assembly, testing, and quality control. This not only speeds up production but also reduces errors, improves consistency, and ensures that machinery meets the highest quality standards.

By implementing these advanced manufacturing solutions, AiDOOS helps manufacturers reduce lead times, improve efficiency, and increase profitability.

Ensuring Compliance and Sustainability:

As industries move toward greener practices, industrial machinery manufacturers must develop energy-efficient machines that comply with environmental regulations. AiDOOS provides access to sustainability and compliance management tools like Bluesign Technologies and Sphera Sustainability Management.

These platforms help manufacturers ensure that their machines meet safety, performance, and environmental standards across multiple markets. By integrating eco-friendly practices into their production processes, manufacturers can develop machines that not only perform well but also minimize environmental impact.

Case Study: Developing Energy-Efficient Turbines for Power Generation

An industrial machinery manufacturer was tasked with developing a new line of turbines for power generation that would meet the growing demand for energy efficiency and sustainability. The turbines needed to reduce carbon emissions and comply with environmental regulations in both Europe and North America.

By partnering with AiDOOS, the manufacturer gained access to experts in turbine design, energy management, and sustainability. Using PTC Creo and ANSYS, the company was able to simulate turbine performance, optimizing the design for efficiency and durability.

Additionally, AiDOOS connected the manufacturer with experts in automation, allowing them to integrate IoT solutions into the turbines for real-time monitoring and predictive maintenance. This reduced downtime and improved operational efficiency, ensuring that the turbines met performance standards and reduced energy consumption by 15%.

The result was a successful product launch that positioned the company as a leader in energy-efficient machinery for the power generation industry.

As industries continue to evolve, the demand for advanced industrial machinery will only grow. Manufacturers must stay ahead of the curve by integrating automation, improving efficiency, and developing sustainable machines that meet the needs of a rapidly changing market.

AiDOOS is helping manufacturers achieve this by providing access to cutting-edge tools, expert talent, and innovative solutions that drive efficiency and innovation in industrial machinery production. From R&D and design to automation and compliance, AiDOOS is empowering manufacturers to create the next generation of industrial machines that power the global economy.

Industrial machinery is essential to modern manufacturing, and the future of this sector lies in innovation, automation, and sustainability. As manufacturers face increasing pressure to develop smarter, more efficient machines, they need the right tools and expertise to stay competitive.

AiDOOS is driving this transformation by connecting manufacturers with the technology, talent, and solutions they need to optimize production, reduce costs, and innovate. As the industrial machinery industry continues to evolve, AiDOOS will remain a critical partner in shaping the future of manufacturing.

For modern telecom enterprises, delivering exceptional QoS is no longer optional—it’s a brand differentiator and a strategic lever for growth. Static provisioning models won’t cut it in a world of hyper-dynamic data usage.