Building the Future: Manufacturing Autonomous Vehicles at Scale

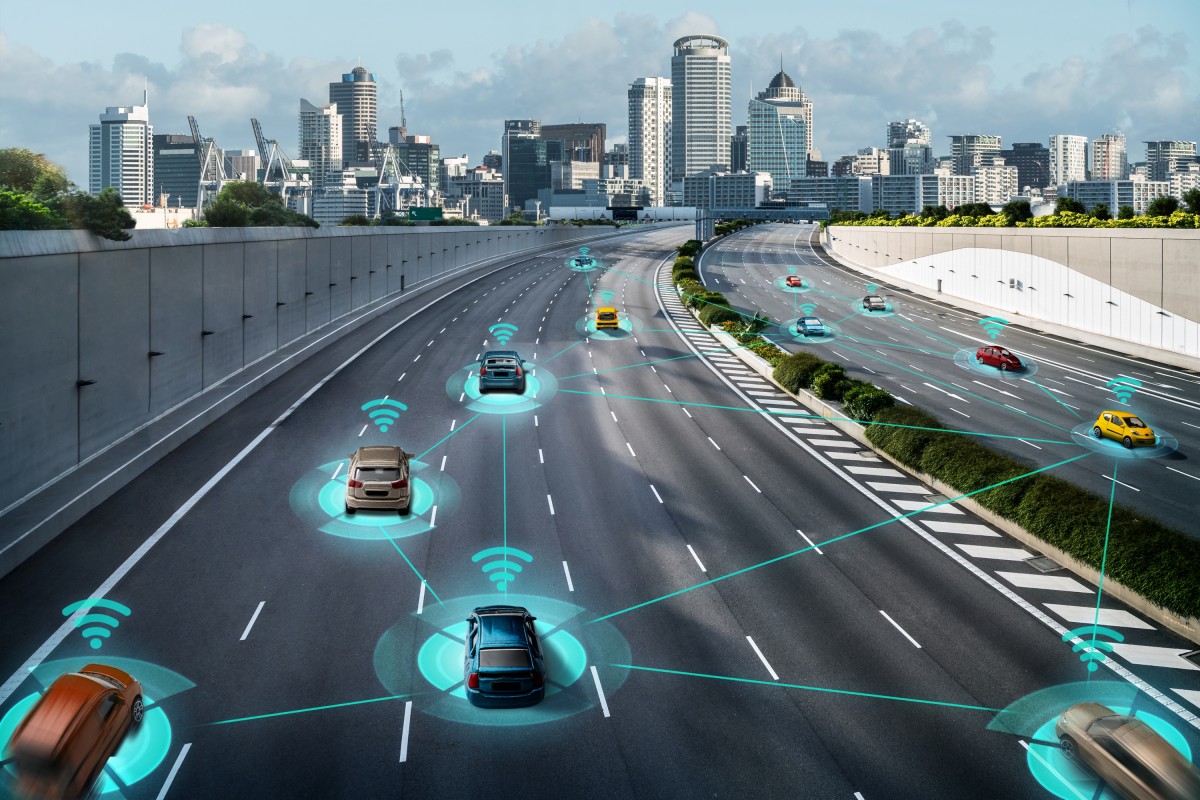

Imagine a world where cars navigate complex city streets, avoid accidents, and park themselves—all without human intervention. This vision is no longer a distant dream. Autonomous vehicles (AVs) are poised to transform transportation, promising safer roads, reduced congestion, and increased mobility for all. However, the journey to manufacturing AVs at scale is a complex interplay of advanced technology, stringent safety standards, and innovative manufacturing practices.

This article explores the intricate process of building autonomous vehicles, diving into the challenges, technological breakthroughs, and the role of collaboration in shaping the future of mobility.

Autonomous vehicles operate on a spectrum of automation, ranging from Level 0 (no automation) to Level 5 (full automation). Each level adds complexity to the manufacturing process:

Level 1-2 (Driver Assistance): Features like adaptive cruise control and lane-keeping assistance.

Level 3 (Conditional Automation): The car can handle specific tasks but requires human intervention.

Level 4-5 (High to Full Automation): Vehicles operate independently in most or all conditions.

Example: Waymo, a leader in autonomous driving, achieved Level 4 automation with its fleet of self-driving taxis in Phoenix, Arizona.

Building AVs is unlike traditional vehicle manufacturing. Challenges include:

a. Sensor Integration:

AVs rely on an array of sensors, including LIDAR, cameras, radar, and ultrasonic sensors. Integrating these into the vehicle’s design while maintaining aesthetics and functionality is a significant hurdle.

b. Computing Power:

Autonomous systems require advanced processors capable of analyzing data from multiple sensors in real-time. Heat dissipation and space constraints add complexity.

c. Safety Validation:

Manufacturing processes must meet rigorous safety standards, including extensive testing for hardware reliability and software robustness.

Anecdote: In 2018, Uber paused its AV testing program after a fatal accident, underscoring the critical importance of exhaustive safety validation.

Manufacturing AVs demands a paradigm shift in production processes. Here’s how manufacturers are adapting:

a. Collaborative Robots (Cobots):

Cobots assist in assembling delicate sensor systems and handling precise tasks, such as aligning LIDAR modules.

b. Digital Twins:

Virtual models of AVs and production lines allow engineers to simulate and optimize every aspect of manufacturing, from sensor placement to software updates.

c. Modular Manufacturing:

AV platforms are designed to be modular, enabling manufacturers to scale production efficiently while customizing vehicles for different use cases.

Case Study: Tesla's Gigafactory uses AI-driven robotics and modular assembly lines to accelerate production of its self-driving vehicles.

Artificial intelligence is central to every stage of autonomous vehicle production:

Design: AI-driven tools simulate real-world driving scenarios to optimize vehicle design.

Production: Machine learning algorithms predict maintenance needs, reducing downtime on production lines.

Testing: AI analyzes sensor data from simulated and real-world tests, ensuring vehicles meet safety and performance standards.

Example: Nvidia’s DRIVE platform provides a comprehensive AI solution for AV design, production, and validation, enabling manufacturers to accelerate development timelines.

The complexity of AV manufacturing has fostered unprecedented collaboration between automakers, tech companies, and suppliers:

Automakers and Tech Giants: Companies like Ford and Argo AI are partnering to develop AV platforms that combine automotive expertise with cutting-edge technology.

Suppliers: Tier 1 suppliers like Bosch and Continental are innovating in sensor technology, contributing to the scalability of AV production.

Governments and Regulators: Collaboration with regulatory bodies ensures that AVs meet safety and ethical standards.

Anecdote: In 2020, GM’s Cruise received a $2 billion investment from Microsoft, highlighting the strategic importance of partnerships in the AV ecosystem.

Autonomous vehicles promise sustainability benefits, but their production must align with green principles:

Energy-Efficient Factories: AV manufacturers are investing in renewable energy and energy-efficient production processes.

Recycled Materials: Incorporating recycled metals and plastics reduces the environmental impact of AV production.

Battery Innovation: Manufacturers are exploring solid-state batteries to power AVs with greater efficiency and lower environmental costs.

Insight: Zoox, an autonomous vehicle startup acquired by Amazon, integrates sustainability into its AV design by using eco-friendly materials and energy-efficient systems.

Manufacturing is just the first step; deploying AVs at scale involves:

Fleet Management: Companies like Waymo are developing software platforms to manage AV fleets efficiently.

Infrastructure Integration: Smart infrastructure, such as connected traffic signals, enhances AV performance in urban environments.

Public Acceptance: Educating the public and addressing safety concerns are critical to widespread adoption.

Example: Baidu’s Apollo project in China integrates AVs with smart city infrastructure, creating a seamless ecosystem for autonomous transportation.

AiDOOS empowers AV manufacturers with tailored solutions to meet their complex needs:

Expert Teams on Demand: Access specialists for AI, robotics, and sensor integration.

SaaS Solutions: Streamline production processes with tools for predictive maintenance, fleet management, and digital twin simulations.

Agility: Scale operations efficiently to adapt to evolving AV technologies and regulatory standards.

The journey to manufacturing autonomous vehicles at scale is as challenging as it is transformative. By embracing cutting-edge technologies, fostering collaboration, and prioritizing sustainability, manufacturers can overcome obstacles and drive the future of mobility. Platforms like AiDOOS offer the agility and expertise needed to navigate this complex landscape, ensuring a seamless transition to the autonomous era.

As autonomous vehicles (AVs) redefine the future of mobility, manufacturing them at scale presents unique challenges—complex supply chains, advanced technologies, and stringent quality standards. Virtual Delivery Centers (VDCs) offer a cutting-edge solution to address these demands efficiently and effectively.

How VDCs Revolutionize AV Manufacturing:

Seamless Integration Across the Ecosystem:

Connect design teams, suppliers, and production units on a single platform for real-time collaboration.

Enable cross-functional teams to work cohesively, reducing development cycles and errors.

Accelerated Innovation with Digital Twins:

Simulate entire manufacturing processes using digital twins to identify bottlenecks and optimize production lines.

Test AV components virtually, ensuring they meet performance and safety standards before physical production.

Supply Chain Resilience:

Monitor global supply chains using predictive analytics to avoid disruptions.

Enhance just-in-time delivery models to manage inventory effectively and reduce waste.

AI-Driven Quality Control:

Use AI and machine learning to automate quality inspections, ensuring precision and compliance with regulatory requirements.

Detect potential defects in real-time, minimizing recalls and enhancing consumer trust.

Workforce Augmentation:

Utilize VDCs to upskill workers in emerging AV technologies and manufacturing techniques.

Facilitate remote operations and oversight, increasing flexibility and reducing dependency on localized resources.

Sustainability and Cost Optimization:

Reduce energy consumption and emissions through optimized production workflows.

Identify cost-saving opportunities without compromising on quality or innovation.

Why VDCs Are Key to Scaling AV Manufacturing:

Speed to Market: Streamlined processes ensure faster product launches in a highly competitive industry.

Agility: Adapt quickly to evolving market demands and technological advancements.

Cost-Effectiveness: Centralized operations and predictive maintenance reduce overheads significantly.

Conclusion:

Virtual Delivery Centers empower manufacturers to scale autonomous vehicle production while meeting the industry’s stringent demands. By adopting VDCs, companies can not only build the future of mobility but do so with unparalleled efficiency, innovation, and sustainability.

Discover how Oracle’s Maintenance Advisor AI agent is transforming equipment maintenance and repair workflows. Learn its enterprise impact, real-world applications, and the future of AI in industrial operations.